When it comes to CNC machining services, it’s common for most industrial clients to confuse between terminologies. Most of them don’t really know the differences between the numerous precision machining processes, and this costs them dearly.

One of the most confused CNC services is CNC turning and CNC milling services. This is because both services are relatively common and achieve a similar goal. Nonetheless, they differ in many ways.

Knowing the difference between these two processes will not only help you make the right decisions; you’ll also yield better results.

Here is a short explanation to clear out all the fuzzy terminology and help you make good decisions.

What is CNC Turning?

CNC turning refers to a machining process where the lathe cuts out extra materials from a rotating workpiece (material being worked on) using its cutting tool. With the cutting tool stationary, CNC turning services basically work on the exterior surface of a workpiece.

The entire process is automated by a computer program and requires minimal supervision. In most machine shops, turning is used to produce cylindrical, threaded and concentric parts.

It’s ideal for mass production, especially if fitted with an automatic bar feeder that ensures raw material supply for the machines. Owing to its rigorous constructions, most CNC turning machines offer little vibration. This allows high accuracy degrees for the surface finishes for most products.

Some of the most common turned materials include steel, copper, hard plastics, brass, aluminum, magnesium and other metal alloys. However, most hard metals are too hard and so require special cutting before undergoing turning.

What is CNC Milling?

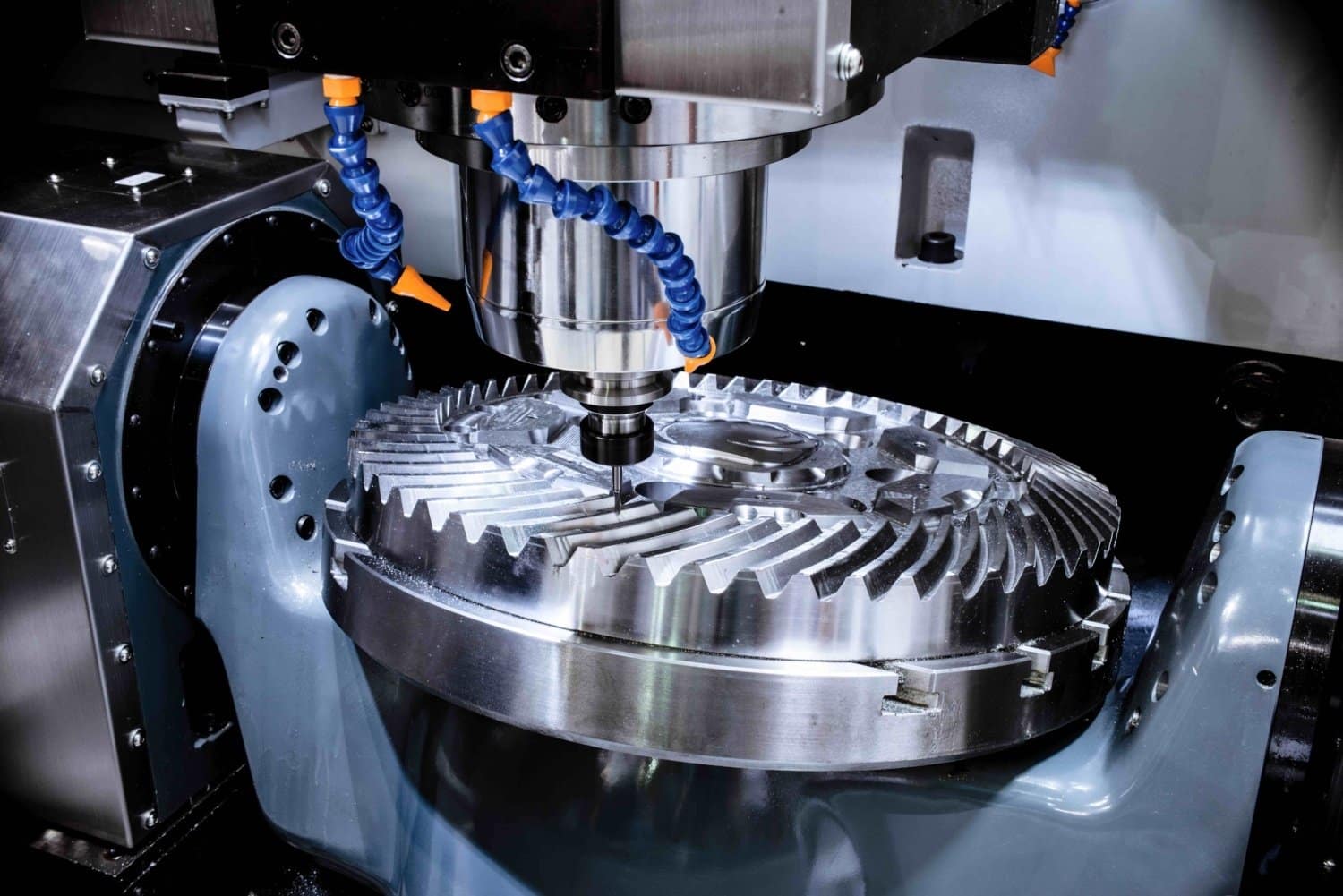

CNC Milling, on the other hand, refers to a machining process where a rotating cutting tool cuts out unwanted material from a stationary workpiece. In this case, the material remains clamped on a machine bed or clamps, while endmills or drills rotate at varying speeds to shave off the material.

The parts milled here are, therefore, not necessarily cylindrical. Some CNC machines achieve high tolerance degrees giving it great versatility and hence more applications in industries.

There are numerous types of CNC milling, each of which is suitable for different industries. The most common of these include Plain milling, angular milling, face milling and form milling.

These different milling types allow industries to produce sophisticated-shaped products easily.

The most commonly milled materials include wood, glass, and metals.

So, what’s the difference?

From the details above, the most obvious difference between these two CNC machining services is their rotation. While they both work to remove extra materials from the workpiece, their rotations allow them to do things differently.

In CNC turning operations, the workpiece rotates as the cutting tool remains stationary while in Milling operations, the cutting tool rotates, and the workpiece remains stationary, clamped on the machine.

These differences in rotation results in different end products. In milling processes, most end parts produced are square-shaped, among other sophisticated shapes. For turning operations, most end products are cylindrical and symmetrical.

Which one should you use?

With that in mind, understanding which process you should use becomes clear. If you’re dealing with round objects like ball bearings, washers, casters or chess pieces, turning is the right option.

For all other shapes, CNC milling is the right operation for you. It offers higher flexibility, meaning you can get nearly any shape produced quickly. It can also work on cylindrical shapes, but its accuracy won’t be as high as that of turning services.

However, you don’t have to choose between these two processes. When combined, milling and turning give you a significant advantage over your competitors. It enables you to achieve higher accuracy and better-quality finishes, which puts you on the map in the market.

Just ensure that you limit the number of times the workpiece moves from one machine to another. The more it’s worked on, the more it losses its quality.

Final Thought

With this knowledge, you’re now better suited to make informed decisions when seeking CNC machining services. Depending on the type of finishes you want in your parts, choose the right process for you!