Are you responsible for maintaining an aluminum coil coating line? If yes, you know that proper maintenance is essential to keeping your line running smoothly and efficiently. And, in this blog post, we’ll give you 5 useful tips to help you look after your aluminum coil coating line properly.

Table of contents

Keep the coils clean

Lubricate the bearings

Inspect the equipment regularly

Train the operators

Devise a maintenance plan

Bottom line

Keep the coils clean

If you want your aluminum coil coating line to run smoothly, one of the most important things is to keep your coils clean. Obviously, dirty coils can cause a buildup of dirt and debris that will clog up the system and make it harder for the line to operate correctly. So, to prevent this buildup, cleaning coils is essential. However, when doing so, it’s important to use only mild soap and water since harsh chemicals and abrasive cleaners can damage the surface of your coils and thus, reduce their lifespan. And, to dive deeper into the process, start by brushing off any dust or dirt from the surface, then wipe them down with a damp cloth. Make sure to also inspect the insides of the coils and remove any debris that may have accumulated there.

Lubricate the bearings

The bearings on the aluminum coil coating line are the main components that allow for the movement of the coils and therefore, must be properly lubricated to ensure that the line runs efficiently.

Overall, the bearings should be lubricated every 500 hours of operation, or once a month, whichever comes first. And, before lubrication itself, it is necessary to clean the bearing surfaces with a solvent or degreaser and remove any debris. However, when applying the lubricant, make sure to use the correct type for the bearings in your line. A general-purpose grease is usually suitable, but it’s better to refer to the manufacturer’s instructions for specific lubricants recommended for your particular equipment.

Inspect the equipment regularly

Inspect all of the parts of the aluminum coil coating line machine regularly, and replace those that are worn or damaged. For instance, inspections should include checking for loose or worn parts, such as nuts and bolts, as well as ensuring that the machine is running smoothly and without any issues.

Additionally, be sure to check for signs of wear on the belts, bearings, and pulleys. And, if you have an automated line, inspect the sensors and electrical components to ensure that they are working correctly. To recap, doing these inspections regularly can help prevent any major breakdowns or malfunctions from occurring in the future.

Train the operators

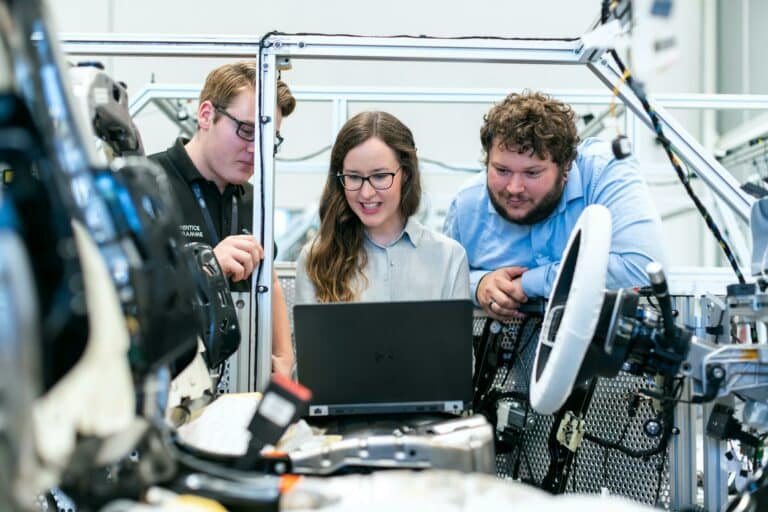

Properly trained operators are key to maintaining a successful aluminum coil coating line. So, it is important that they are familiar with all of the safety protocols, operating procedures, and best practices. Besides, make sure the staff are aware of the potential hazards of working with an aluminum coil coating line and provide adequate instruction on how to properly handle the equipment, even in case of emergency.

Without a doubt, the best way to impart a thorough understanding of the process is to provide hands-on training. So, allow the workers to practice operating the equipment and running test batches so that they can gain an in-depth understanding of what is expected of them.

Plus, it is important to keep your operators up-to-date on any new processes or technology that may be introduced in future.

Devise a maintenance plan

Having a maintenance plan in place is essential for the proper functioning of your aluminum coil coating line. In general, a well-thought-out maintenance plan should include:

• Scheduled preventative maintenance, so you can identify and address any potential issues before they become major problems.

• Spare parts on hand, in case of any breakdowns or malfunctions.

• Procedures for addressing any customer complaints or feedback about the product.

And, if you need help creating a solid maintenance plan, contact professionals who specialize in aluminum coil coating lines to design a plan tailored to the company’s needs.

Bottom line

Maintaining an aluminum coil coating line properly is essential for the longevity of the machine, as well as the quality of the products made. So, with the 5 aforementioned tips in mind, you can be sure that your aluminum coil coating line will run smoothly and efficiently for many years to come.